Bellows Design & Manufacturing Process

1. Metal bellows manufacturing starts with the customer’s selection of ASTM or ASME material based on system design. Bellows ply thickness, number of convolutions, and convolution height and pitch are determined by Badger. Typical ply thickness for metal bellows ranges from .010” to .078”. Minimum thickness is .005” and maximum thickness is .125”, depending on the forming method used.

2. The bellows material is sheared to close tolerance dimensions depending on diameter and final convoluted length.

3. The material is then rolled into a tube, welded, and planished (shown on the left in the above image).

4. The tubes are then processed on a bellows forming machine to Badger design requirements (shown on the right in the above image).

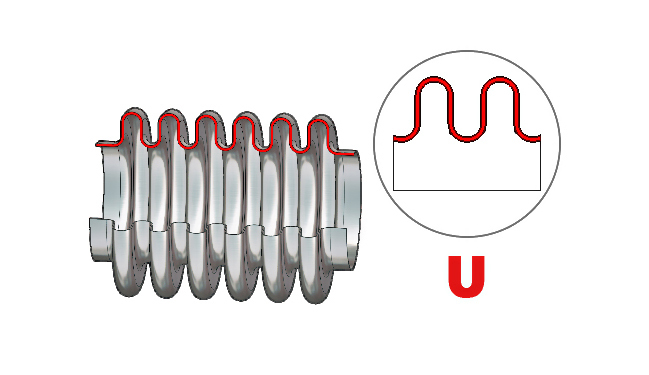

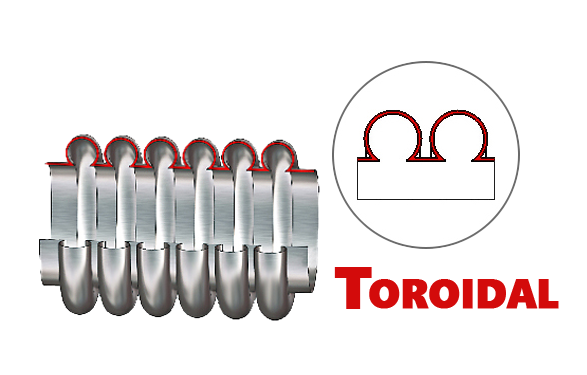

Metal Bellows Convolution Shapes

Typical convolution shapes are: U Shape and Toroidal

Related Downloads:

Knowledge Base Handbook for Metal Bellows Expansion Joints

Knowledge Base Handbook for Metal Bellows Expansion Joints

Knowledge Base Handbook for Metal Bellows Expansion Joints